How Monsoon Affects Textile Printing: Challenges & Practical Solutions

Share

The monsoon is a season of renewal — but for textile printers it brings specific technical challenges. From increased humidity that alters dye behaviour to slower drying and logistical delays, understanding monsoon impacts is essential for maintaining product quality. Below we explain the major effects and share the practical steps we use at Srishti Textile to keep prints vibrant and deliveries reliable.

Humidity & Dye Absorption

High atmospheric moisture changes how dyes interact with cotton and blended fabrics. Natural dyes and reactive dyes both show slower fixation — which can cause unevenness or subtle bleeding. To manage this, we measure relative humidity throughout the production floor and adjust dye concentrations and exposure times accordingly.

Drying Delays and Fabric Curing

During the dry season fabrics may cure within hours; in monsoon they might take days. Delayed drying increases the risk of mildew and color migration. Our solution: semi-covered drying chambers with controlled ventilation and batch rotation to ensure consistent cure and quality checks at each stage.

Natural Dye Behavior

Natural dyes (indigo, madder, turmeric-based shades) are sensitive to moisture. Indigo, for example, oxidizes more slowly in humid air; resist pastes used in Dabu or mud-resist printing need extra setting time. We use carefully tested natural fixatives and controlled post-print washing protocols to maintain color consistency.

Storage & Quality Assurance

Finished rolls stored in damp conditions can suffer odor and fungal growth. We store finished inventory on elevated racks with silica gel packs and ensure regular air circulation. Each product goes through a final QC checklist—colorfastness, odor check, and seam inspection—before packing.

Logistics & Delivery Planning

Monsoon can disrupt transport and increase transit times. To reduce customer impact, we use moisture-resistant packing and collaborate with reliable courier partners. For wholesale shipments, we stage production and use consolidated shipments when roads and ports are less affected.

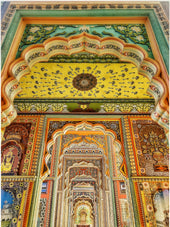

Design Opportunities During Monsoon

The season also inspires new design palettes: muted indigos, stormy greys, and earthy browns. At Srishti Textile we translate monsoon moods into gentle prints that resonate with seasonal buyers.

Conclusion

Monsoon challenges require operational foresight and craft adjustments—but they don't need to halt production. With humidity control, modified dye protocols and robust storage practices, printers can continue to deliver high-quality hand-block and machine-printed textiles even during the rains. If you'd like to source monsoon-resistant prints or request a sample, visit our product pages below.

Dress Material Manufacturer — Request Samples Bedsheet Collection — Bulk Orders